Method for laying composite geomembrane

Composite geomembrane is a geotextile anti-seepage material composed of plastic film as the anti-seepage substrate and non-woven fabric. Its anti-seepage performance mainly depends on the anti-seepage performance of the plastic film. At present, plastic films for anti-seepage applications both domestically and internationally mainly include (), polyethylene (PE), and ethylene/vinyl acetate copolymer (EVA). They are a type of polymer chemical flexible material with a small specific gravity, strong extensibility, and high adaptability to deformation. Corrosion resistance, low temperature resistance, and good frost resistance.

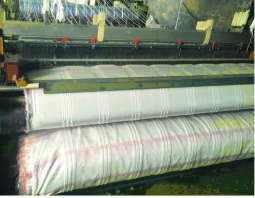

Composite geomembrane

So what should be noted when choosing composite geomembranes? Geomembrane manufacturers will introduce to you.

The composite geomembrane must comply with the technical standard "Geosynthetic Materials Non woven Composite Geomembranes" (GB/T17642-1988). The selection of composite geomembranes must be from reputable manufacturers, and must have inspection reports from authoritative enterprises for verification, as well as product qualification certificates; Characteristics and indicator values, as well as user manuals, and authorization to commission a third-party platform to conduct inspections on the product. Only after passing the inspection can it be applied. When selecting the total width of composite geomembranes, it is necessary to ensure that the membrane joints are at least as wide as possible, taking into account the thickness requirements. The geomembrane delivered to the site should be used up on the same day.

The selection of composite geomembrane specifications is related to the flatness of the underlying layer, the allowable tensile stress of the material, the elastic modulus of the material, the large water head within the laying range, and the large particle size of the covering layer. In addition to considering the strength required by water pressure, the thickness design also needs to consider application conditions such as exposure, burial pressure, climate, and service life, and determine the design thickness and actual thickness according to the current relevant standards.